Ever tried to solder something and ended up with a messy blob? You’re not alone. Soldering can be tricky! But there’s a secret weapon many beginners overlook: solder flux. This magical stuff helps your soldering joints come out shiny and strong.

Contents

So, What Is Solder Flux?

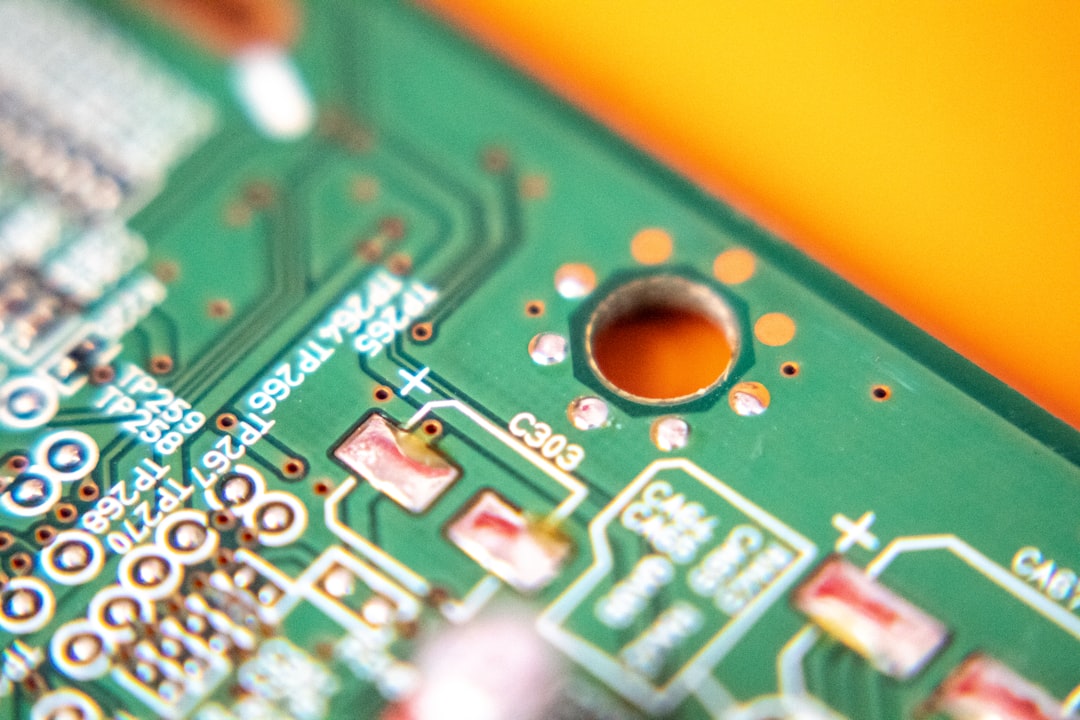

Solder flux is a chemical agent. It’s used to clean surfaces during the soldering process. When metals heat up, they oxidize. This oxidation makes it harder for solder to stick. That’s where flux steps in. It removes oxidation and prevents more from forming while you solder.

Think of flux as a helper that holds the door open for the solder to flow freely.

Why Is Flux So Important?

Without flux, your solder might not stick well. You could end up with weak joints that break easily. Or worse, you might have a bad connection that’s hard to find later.

Here’s what flux does:

- Cleans the metal surfaces

- Prevents further oxidation

- Improves the flow of solder

- Helps create strong, shiny joints

Types of Solder Flux

Flux comes in different types. Each one has its own use. Let’s look at the three most common:

- Rosin Flux – This is made from natural tree sap. It’s great for electronics because it doesn’t conduct electricity. But it needs to be cleaned after soldering.

- No-Clean Flux – Just what it sounds like! It leaves minimal residue, so you usually don’t need to clean it. Perfect for quick jobs.

- Water-Soluble Flux – Stronger than the others. It cleans really well but needs to be washed off with water. Often used in industries.

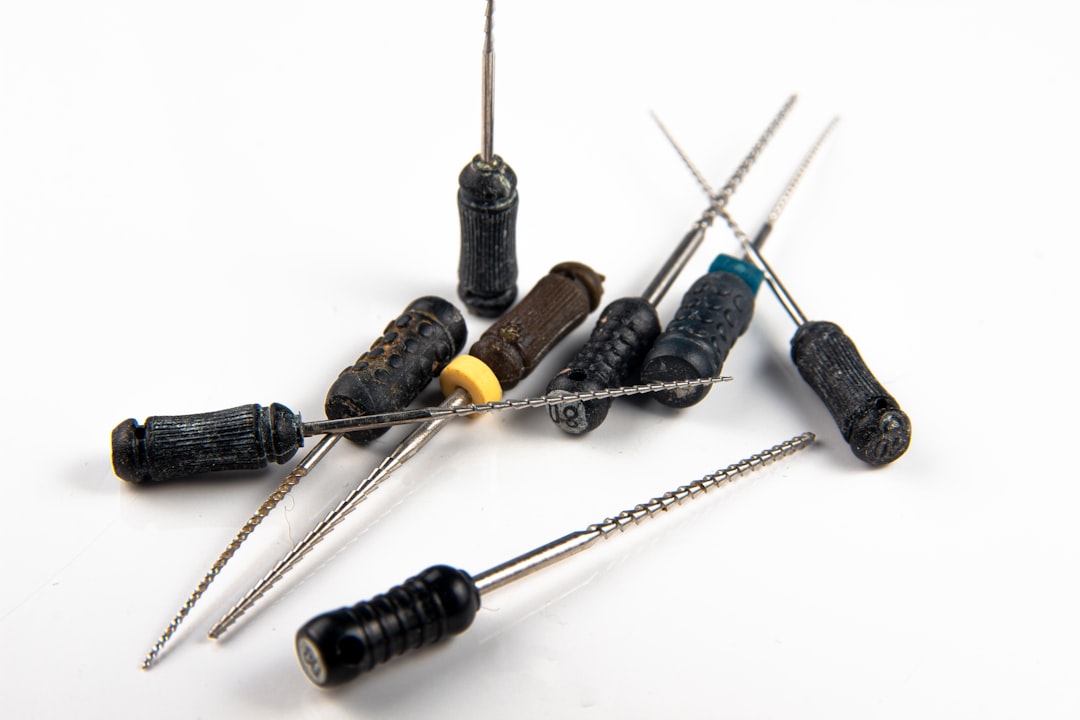

Forms of Flux

Flux also comes in many forms. Some common ones are:

- Liquid – Easy to apply with a brush or pen

- Paste – Thicker and stays in place better

- Flux Core Solder – The flux is already inside the solder wire

Beginners often start with flux core solder because it’s the easiest to use.

How to Use Solder Flux

Using flux isn’t complicated. But doing it right makes a big difference!

Step-by-Step Guide

- Clean the parts – Use isopropyl alcohol or a cleaner. Get rid of any dirt or grease.

- Apply flux – Use a small amount. You can brush it on, squeeze it, or draw it with a flux pen.

- Heat the joint – Use your soldering iron to heat the area where you’re joining two metals.

- Add solder – Once the metal is hot, touch solder to the joint (not the iron). The solder should flow smoothly.

- Clean up – If the flux leaves residue, clean it off with alcohol and a toothbrush.

Tips and Tricks

- Don’t overdo it! – A tiny bit of flux goes a long way.

- Store it well – Keep your flux sealed and away from heat or sunlight.

- Use the right type – Pick the right flux depending on your project.

- Practice – Try on scrap pieces before working on your actual project.

Common Mistakes

Here are a few things to watch out for:

- Too much flux – It can get messy and make cleanup tough.

- Not cleaning residue – If you leave residue, it can corrode the boards or cause short circuits.

- Soldering too cold – If your iron isn’t hot enough, the solder won’t flow right.

Where Is Flux Used?

You’ll find solder flux being used all over the place, including:

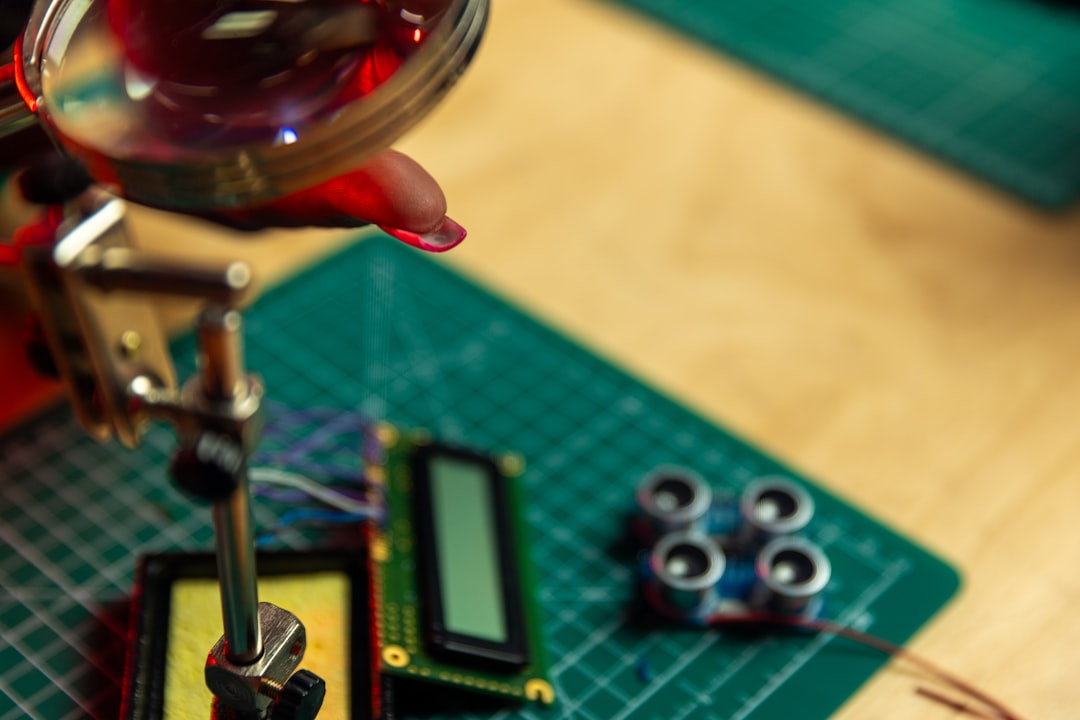

- Electronics repair – Fixing phones, computers, and other devices

- Making circuits – Joining wires and components on a PCB

- Jewelry making – Yep, flux is also used when soldering metal jewelry!

- Plumbing – Different kind of flux, but similar idea

How to Choose the Right Flux

Think about what you’re working on. Want to fix a game controller? Use no-clean flux. Building a PCB from scratch? Try rosin or water-soluble, depending on your tools.

Still not sure? Here’s a quick guide:

| Project Type | Best Flux |

|---|---|

| Electronics repair | No-clean |

| Professional PCB work | Water-soluble |

| Everyday DIY | Rosin |

| Plumbing | Acid-based (not for electronics!) |

Safety First!

Flux is helpful, but also a bit sneaky. Some kinds smoke when heated. Others leave acidic residue. Make sure you:

- Work in a well-ventilated area

- Wear safety glasses

- Wash hands afterward

- Avoid breathing fumes – A small fan or fume extractor helps

A Quick Story…

Let’s say you’re fixing a remote control. You open it up and notice a broken solder joint. You add a bit of flux, touch it with a hot iron, and boom – the solder flows perfectly. The remote works again. Just like magic… only it’s science!

The Final Touch

So, what’s the big takeaway? Flux is your friend. It makes your solder work better, look better, and last longer. Don’t skip it!

Whether you’re a hobbyist or a future engineer, adding flux to your toolkit is a smart move. It’s a small step that makes a huge difference.

Now grab that soldering iron and make something awesome!