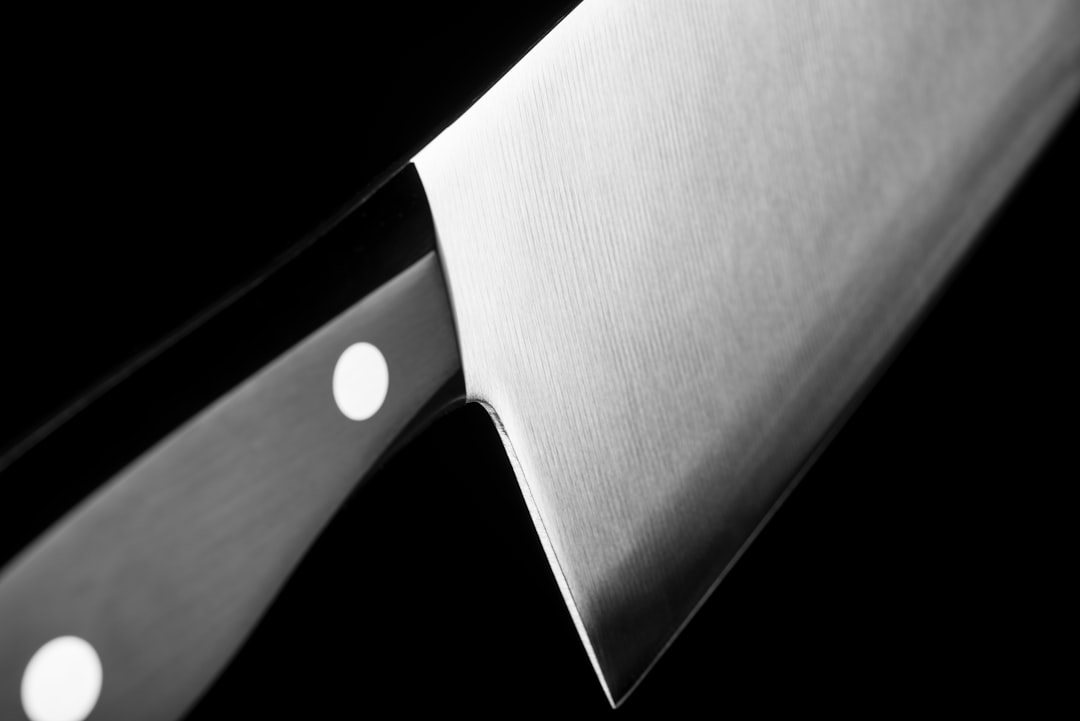

Whether in the context of high-precision cutting tools, hunting broadheads, or even military applications, blade design plays a critical role in determining not just how well a blade penetrates a target, but also how it performs after initial contact. The geometry, material composition, and edge configuration all contribute to the final effectiveness of a blade. With advancing technology, professionals and enthusiasts alike benefit from understanding how these variables influence overall performance.

Contents

TLDR:

Blade design significantly impacts a blade’s penetration efficiency and its behavior post-impact. A sharper, thinner edge tends to allow deeper initial cuts, while blade width and shape determine stability and tissue displacement. Technological advancements in materials and manufacturing have made blades more durable, aerodynamic, and task-specific. Whether for surgical use, outdoor gear, or tactical tools, understanding blade science ensures optimal performance.

The Fundamentals of Blade Design

Blade design encompasses various attributes that directly influence performance, especially when it comes to penetration — the ability of a blade to enter a target with minimal resistance — and post-penetration behavior, such as cutting, tearing, or channeling through the material. Here are some of the primary factors involved:

- Blade angle and grind

- Blade thickness

- Tip design

- Blade materials

- Surface finish and edge treatment

1. Blade Angle and Grind

The grind of a blade refers to the shape of the blade edge as it tapers to the final cutting bevel. Common types include flat grinds, hollow grinds, convex grinds, and compound grinds. Each influences what the blade is optimized for:

- Flat grind: Offers a balance between sharpness and durability. Excellent for slicing tasks.

- Hollow grind: Extremely sharp but thinner and less durable — best for fine cutting.

- Convex grind: Enhances durability and penetrates thicker targets with more structural integrity.

The more acute (sharper) the cutting angle, the greater the blade’s initial penetration. However, a very fine edge may chip or deflect if not backed by a supportive grind geometry.

2. Blade Thickness and Width

Thicker blades naturally have more strength behind the tip, but they also experience more resistance when entering a material. Conversely, thinner blades can penetrate more easily but might bend or break under stress. Blade width affects stability during penetration:

- Wider blades help keep the trajectory stable by resisting direction change once penetration begins.

- Narrow blades reduce drag and are better suited for deep penetration, but can be less stable.

3. Tip Geometry

Perhaps the most directly influential factor in penetration is tip design. Blade tips come in many shapes, with each delivering unique advantages:

- Tanto tip: Designed for strength. Useful in tactical or piercing applications.

- Drop point: Offers a balance between sharp tip and structural resilience. Good for controlled piercing.

- Spear point: Excellent for symmetrical penetration with minimal deviation.

- Needle point: Maximizes initial penetration, minimizes surface drag — highly effective at piercing but prone to breakage.

The sharper and more streamlined the tip, the less resistance it encounters during entry, resulting in better penetration. However, this also raises concerns about durability, especially in bone or hard-surface contacts.

4. Blade Material and Hardness

The composition and heat treatment of a blade directly affect its hardness, flexibility, and durability, all of which determine performance:

- High carbon steel: Excellent edge retention and durability, but more prone to rust.

- Stainless steel: Rust-resistant and tough, though may require more frequent sharpening.

- Ceramic blades: Extremely sharp and rust-proof, but brittle and not ideal for forceful penetration.

Heat treatment processes such as tempering and cryogenic treatment can also influence blade hardness and impact resistance. The goal is to strike a balance: hard enough to cut cleanly, tough enough to resist chipping and deformation.

5. Edge Finish and Sharpness

The quality of the blade edge and finish can reduce friction and improve cutting efficiency. A highly polished blade surface will move through material more smoothly, creating less resistance. On the other hand, certain textured or micro-serrated edges may enhance sawing or dragging effects in fibrous targets like fabric or tissue.

Sharpness, of course, is a critical factor. Even the best-designed blade will underperform if it’s dull. Regular maintenance, along with technological improvements in edge retention, ensure sustained performance over time.

6. Aerodynamics and Flight Stability (Relevant for Thrown or Projectile Blades)

In the case of projectile blades such as broadheads used in archery and even some military munitions, aerodynamic design is paramount:

- Ventilation holes reduce wind drag and oscillation.

- Symmetrical blade arrangement enhances spin stability.

- Weight distribution determines the trajectory and point of impact accuracy.

These aerodynamic factors contribute heavily not only to successful impact but also to the angle and depth at which the blade penetrates, influencing post-impact behavior and wound channeling.

7. Cutting vs. Tearing vs. Channeling

Once a blade penetrates a target, how it continues to behave — whether it cuts cleanly, tears, or creates a channel — depends again on its design.

- Broad, sharp blades: Create longer incisions with clean entry and exit paths.

- Serrated edges: Tend to create tearing effects, ideal for fibrous material like rope or skin with layers of muscle.

- Multi-blade designs (e.g., broadheads): Increase wound diameter, reducing clotting and causing rapid incapacitation during hunting or defense scenarios.

Understanding the intended outcome helps in choosing the appropriate blade type. A surgical blade, for instance, focuses on precision and clean incisions, while a tactical or hunting knife often aims for more destructive results.

Recent Technological Advances

Modern advancements in materials science and manufacturing methods have revolutionized blade performance. Innovations include:

- Powder metallurgy: Allows for uniform grain structure in steel, leading to super-strong and flexible blades.

- Laser and waterjet grinding: Precision sharpening that reduces imperfections and increases durability.

- Carbon-nanotube-reinforced materials: Experimental, but showing promise in achieving unmatched strength-to-weight ratios.

Manufacturers now use computer-aided modeling to simulate blade interaction with various materials, optimizing every curve and angle before creating a physical prototype.

Conclusion

Blade design affects far more than just appearance or brand identity. The shape, materials, and engineering decisions behind a blade dictate its penetrative power, durability, and functionality in real-world scenarios. Whether you’re a knife enthusiast, outdoor adventurer, or someone working in high-precision industries, understanding the science of blade design can greatly enhance your ability to choose the right tool—and use it effectively.

Whether slicing, piercing, or chopping, every blade has a story written into its steel. By learning how design affects performance, you’re better equipped to read that story and, perhaps, write a few chapters of your own.