Over the years, automotive technology has advanced in remarkable ways. While many new features and upgrades have enhanced vehicle safety and comfort, some older mechanisms—like the traditional turn-signal stalk—remain irreplaceable for many drivers. Recently, a growing trend toward retrofitting modern or minimalist cars with traditional turn-signal stalks has captured the attention of safety experts and enthusiasts alike. Why? Because the way we interact with our vehicles plays a direct role in road safety.

TLDR: Turn-signal stalk retrofits are becoming more popular as a response to touch-sensitive interfaces in modern cars. While they can improve driver ergonomics and reduce distraction, safety testing is crucial before such retrofits are widely adopted. Testing examines reaction times, failure points, and compatibility with existing systems. These retrofits could be a step forward in balancing modern design with proven safety features.

Contents

Why Retrofit a Turn-Signal Stalk?

Modern car interiors increasingly favor sleek touchscreens and minimalist dashboards. In some cases, traditional stalk-based controls for signals, wipers, and cruise control are being replaced with buttons on a touchscreen or steering wheel. Although these alternatives look futuristic, they pose a critical concern: driver distraction.

Turn-signal stalks provide a tactile, muscle-memory-based way to indicate turning intentions without having to look away from the road. By contrast, drivers often need to take their eyes off the road to locate and activate signal buttons on a screen or surface.

- Improved ergonomics: Drivers are already conditioned to use stalks, making them easier and quicker to operate.

- Safety enhancement: Reduces the need for visual confirmation, allowing drivers to stay focused.

- Reliable mechanical feedback: Traditional stalks offer distinct resistance and click, assuring users of successful activation.

In response, aftermarket parts manufacturers and engineers have started developing retrofit kits to incorporate turn-signal stalks back into modern vehicles. However, these modifications bring up important safety concerns that call for rigorous testing.

What Is Safety Testing in This Context?

Safety testing for turn-signal stalk retrofits involves a combination of laboratory simulations, field trials, and human factor studies. The focus is to ensure that these add-ons do not compromise the functionality of existing systems or introduce new risks.

Generally, the core areas of safety testing include:

- Response Time Analysis: How quickly can a driver activate a signal using the retrofit compared to the OEM interface?

- Mechanical Durability: How long can the component remain functional under stress and repeated daily use?

- Malfunction Impacts: What happens if the stalk fails—does it affect other vehicle electronics or safety systems?

- Compatibility: Does the stalk integrate cleanly with the vehicle’s onboard computer and CAN Bus systems?

- User Behavior Trials: How do real drivers interact with the retrofit? Does it reduce or increase distraction?

Each of these metrics is measured not only in isolated settings but also in real-world driving environments, both on closed test tracks and public roads over time.

Testing Methodologies

There are two broad categories used in safety testing for retrofitted turn-signal stalks: lab-based simulations and real-world pilot tests.

Lab-Based Simulations

In a controlled lab setting, engineers use dynamometers and electronic test benches to simulate vehicle electrical systems. Turn-signal stalks are connected to these systems to evaluate:

- Electrical compatibility and current draw

- Signal transmission accuracy via CAN or LIN bus protocols

- Delay or lag in activation and deactivation signals

- Integration with other systems like headlamps, cruise control, and collision avoidance

Environmental chambers are also employed to simulate temperature extremes and moisture to test whether the stalk can hold up under diverse conditions.

Real-World Testing

Real-world tests provide insights that can’t always be captured in a lab. Testing is done on-road with professional and volunteer drivers using retrofitted cars under varying traffic and weather conditions.

Tests gather data on metrics like:

- Driver distraction levels (measured via eye-tracking and cognitive workload assessments)

- Hazard perception during lane changes and turns

- Frequency and accuracy of signal usage

- Ergonomics, including hand reach and comfort

These studies typically use instrumented vehicles equipped with data logging devices that monitor every interaction with the turn-signal system, along with downstream responses from the car’s safety systems.

Challenges in Retrofitting Stalks

Adding an aftermarket turn-signal stalk isn’t as simple as bolting it on. Vehicles now rely on highly-integrated digital systems, meaning that even a minor control like a turn-signal affects multiple sub-systems.

Here are some of the key challenges:

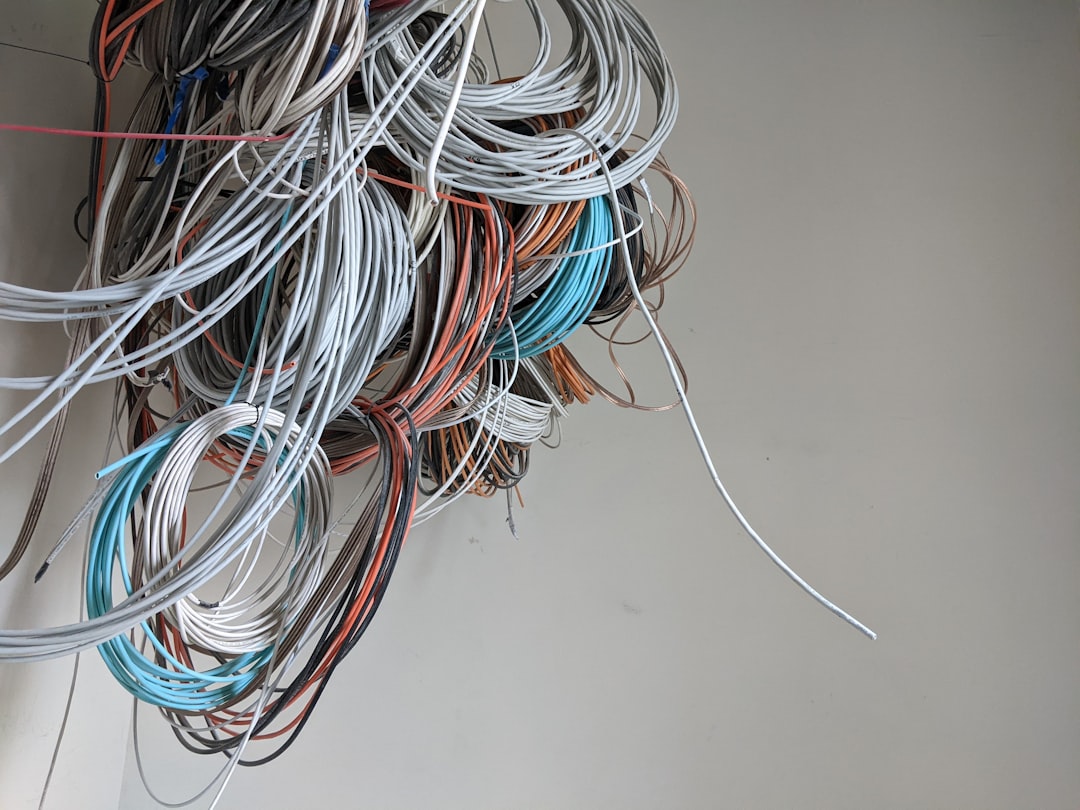

- CAN Bus communication: If the vehicle’s computer doesn’t recognize the stalk’s signals, it may throw diagnostic trouble codes or even disable other systems.

- Physical mounting: Modern steering columns are often designed without any mounting points for stalks.

- Firmware updates: Vehicle software might need to be updated to recognize and respond properly to stalk input.

Because of this complexity, each retrofit must be judged on a case-by-case basis, and extensive testing is crucial before a product hits the broader market.

Innovations in Retrofit Safety

To mitigate the risks of retrofitting, some companies have introduced new technologies and design features:

- Plug-and-play modules: These allow easy integration with the vehicle’s electrical system without complex wiring or programming.

- Adaptive signal mapping: Smart microcontrollers that learn from the vehicle’s native signal system and mimic the necessary data signals.

- Fail-safes and diagnostics: Built-in diagnostic LEDs and error logging features improve maintainability and safety assurance.

Additionally, some developers work closely with aftermarket ECU tuning experts to ensure their systems are adaptable and don’t interfere with pre-existing safety or emissions standards.

What Do The Results Show?

Preliminary safety testing reports from third-party evaluators show promising results for turn-signal stalk retrofits:

- Up to 30% reduction in distracted driving indicators in vehicles with stalk retrofits compared to touchscreen-only controls

- Improved reaction times in emergency lane change scenarios by up to 250 milliseconds

- Minimal electrical failure rates when properly installed with compatible vehicles

However, vehicle-to-vehicle variability remains a concern. Some retrofits work flawlessly on certain models but require major tailoring for others. Hence, standardized retrofit kits are not available for every vehicle platform just yet.

Conclusion: Is It Worth It?

Turn-signal stalk retrofits are more than just a nostalgic nod to the past—they can actively improve driving safety in an era where user interfaces often prioritize aesthetics over ergonomics. But this benefit comes with the caveat of rigorous testing. It’s essential that each retrofit is subjected to stringent safety validation before being considered viable for everyday use.

With ongoing innovation and manufacturer collaboration, these retrofits may soon serve as a bridge between cutting-edge design and time-proven control systems. For drivers who value tactile feedback and minimal distraction, retrofitted turn-signal stalks might just be the feature they didn’t know they needed.